Event & News

Supply chains as truly strategic differentiators

The fragility of the global supply chain has never been more top-of-mind than it is now, and it’s time to focus our efforts on more than just restoring our previous capabilities. Instead, we need to build new levels of resiliency into our networks of suppliers and stakeholders. Those capabilities require a hard look at how we collect and use data from across our network, and digitalization investments that can empower businesses to predict and pivot when disruption occurs.

It’s safe to say the supply chain is no longer an overlooked or underappreciated part of the business. Over the past decade, the explosion of e-commerce and consumer expectations ran headlong into the natural disasters and geopolitical uncertainty of our world, and the C-Suite began appreciating robust supply chains as truly strategic differentiators. The pandemic served as an accelerator, putting supply chain top of mind for every business leader. A mid-pandemic IT spending survey from IDC found 57% of respondents had their supply chains “significantly affected,” while another 27% said they were anticipating supply chain disruption soon.

The IDC survey also highlighted “resiliency” as a top supply chain concern, followed closely by a lack of digital competence to transition supply chains into new business models. The resiliency of your business dictates whether the gap between a business’ slowdown and its eventual recovery will be a wide canyon, or a small trench that can be overcome with smart decisions informed by the right information. But those survey responses indicate many businesses don’t believe they have the right digital tools or expertise to pivot their supply chain operations in the face of disruption or shifts in business focus (e.g., the ability to shift production from producing paper products to nasal swabs).

That inability to respond to change quickly is a problem that needs to be addressed. By using virtual environments to create a collaborative system where all stakeholders can see what’s happened in the past and what’s happening right now, businesses can create simulations to analyze and optimize their paths forward--and find the resiliency to weather a coming storm.

But the lessons we learn aren’t going to change the fundamentals of our industry. If supply chain managers have the agility to respond both proactively and reactively to a demand or supply disruption and can present that insight to decision-makers sooner than anyone else, that business will have a competitive advantage. Virtual twins provide the framework for stress-testing in preparation for the next global disruption. Whether it’s a stuck ship causing a global traffic jam or a natural disaster, companies that invest in resiliency will be positioned to make adjustments and emerge from the crisis stronger than before.

Source: https://www.industryweek.com/supply-chain/supply-chain-technology/article/21171696/stress-testing-for-the-next-supply-chain-disruption

Read MoreIt’s safe to say the supply chain is no longer an overlooked or underappreciated part of the business. Over the past decade, the explosion of e-commerce and consumer expectations ran headlong into the natural disasters and geopolitical uncertainty of our world, and the C-Suite began appreciating robust supply chains as truly strategic differentiators. The pandemic served as an accelerator, putting supply chain top of mind for every business leader. A mid-pandemic IT spending survey from IDC found 57% of respondents had their supply chains “significantly affected,” while another 27% said they were anticipating supply chain disruption soon.

The IDC survey also highlighted “resiliency” as a top supply chain concern, followed closely by a lack of digital competence to transition supply chains into new business models. The resiliency of your business dictates whether the gap between a business’ slowdown and its eventual recovery will be a wide canyon, or a small trench that can be overcome with smart decisions informed by the right information. But those survey responses indicate many businesses don’t believe they have the right digital tools or expertise to pivot their supply chain operations in the face of disruption or shifts in business focus (e.g., the ability to shift production from producing paper products to nasal swabs).

That inability to respond to change quickly is a problem that needs to be addressed. By using virtual environments to create a collaborative system where all stakeholders can see what’s happened in the past and what’s happening right now, businesses can create simulations to analyze and optimize their paths forward--and find the resiliency to weather a coming storm.

But the lessons we learn aren’t going to change the fundamentals of our industry. If supply chain managers have the agility to respond both proactively and reactively to a demand or supply disruption and can present that insight to decision-makers sooner than anyone else, that business will have a competitive advantage. Virtual twins provide the framework for stress-testing in preparation for the next global disruption. Whether it’s a stuck ship causing a global traffic jam or a natural disaster, companies that invest in resiliency will be positioned to make adjustments and emerge from the crisis stronger than before.

Source: https://www.industryweek.com/supply-chain/supply-chain-technology/article/21171696/stress-testing-for-the-next-supply-chain-disruption

7 ways in which a supply chain can fail.

Fixating on the pursuit of managing risks in supply chains is like chasing wind in that it is impossible to capture the unlimited sources of risk, with each one representing a different cause for the supply chain failure. Supply chain risks fall into general categories such as natural disasters (the Tohoku earthquake and tsunami), industrial accidents (the port explosion in Beirut), infrastructure failure (Trans-Siberian railroad bridge collapse), terror attacks (the Colonial pipeline shutdown), and labor action (the US West Coast lockout), to name but a few. General Motors counted over 120 different high-level financial, strategic, operational and hazard risks, and these can expand into thousands of risks when applied at an operational level.

Given the extent of the risk universe, it is impractical for organizations to create mitigation plans for every type of threat. Instead, they should seek to manage the most critical risks, and make their supply chains resilient enough to endure disruptions – including those that are outside of their control.

Hence, risk management is about reducing the probability of experiencing the impact of a risk event, while resilience is about creating the ability for the supply chain to continue operating in the face of a risk event or disruption. Moreover, the need for resilience is not negated by managing risk. Reducing the probability and severity of a disruption can reduce the need for resilience – but it doesn’t eliminate it.

Making a supply chain resilient implicitly involves creating business continuity plans (BCPs) to ensure continued operations in the face of a supply chain disruption. These are plans to restore lost capacities, independent of HOW the operational capacities were lost.

The good news is that there are only seven ways in which a supply chain can fail. Each failure (also known as failure mode) involves the loss of at least one of the core capacities listed:

• The capacity to acquire materials (maintain supply).

• The capacity to ship and/or transport products.

• The capacity to communicate.

• The capacity to convert (internal manufacturing operations).

• The human resources (personnel) capacity.

• The capacity to maintain financial flows.

• The capacity to distribute products to customers including consumers.

Regardless of how the capacity was lost (due to natural disaster, industrial accident, infrastructure failure, for example), the outcome is predictable – capacity loss.

Framing possible operational failures in this way gives rise to a powerful approach to building resilience in supply chains. In this approach, companies focus on avoiding or managing a limited number of predictable outcomes. In other words, while the sources of risk are unlimited, the outcomes of risk events are not.

Source: https://www.scmr.com/article/the_seven_core_capacities_of_supply_chain_resilience

Read MoreGiven the extent of the risk universe, it is impractical for organizations to create mitigation plans for every type of threat. Instead, they should seek to manage the most critical risks, and make their supply chains resilient enough to endure disruptions – including those that are outside of their control.

Hence, risk management is about reducing the probability of experiencing the impact of a risk event, while resilience is about creating the ability for the supply chain to continue operating in the face of a risk event or disruption. Moreover, the need for resilience is not negated by managing risk. Reducing the probability and severity of a disruption can reduce the need for resilience – but it doesn’t eliminate it.

Making a supply chain resilient implicitly involves creating business continuity plans (BCPs) to ensure continued operations in the face of a supply chain disruption. These are plans to restore lost capacities, independent of HOW the operational capacities were lost.

The good news is that there are only seven ways in which a supply chain can fail. Each failure (also known as failure mode) involves the loss of at least one of the core capacities listed:

• The capacity to acquire materials (maintain supply).

• The capacity to ship and/or transport products.

• The capacity to communicate.

• The capacity to convert (internal manufacturing operations).

• The human resources (personnel) capacity.

• The capacity to maintain financial flows.

• The capacity to distribute products to customers including consumers.

Regardless of how the capacity was lost (due to natural disaster, industrial accident, infrastructure failure, for example), the outcome is predictable – capacity loss.

Framing possible operational failures in this way gives rise to a powerful approach to building resilience in supply chains. In this approach, companies focus on avoiding or managing a limited number of predictable outcomes. In other words, while the sources of risk are unlimited, the outcomes of risk events are not.

Source: https://www.scmr.com/article/the_seven_core_capacities_of_supply_chain_resilience

Supply Chains Resiliency

For many years, companies have invested to become more agile and slimmer, operating at higher and higher efficiencies. Resiliency, on the other hand, demands a company’s capability to deal with the unexpected. As an example, investing more in certain types of raw material inventory may reduce efficiency however is the premium to ensure availability of the products when an unexpected event causes disruption in the delivery of these raw materials.

Resiliency also implies having multiple sources of supply from different regions and different suppliers. Given the current geopolitical and socioeconomic dynamics in the world, it is highly unreliable to depend on a single source of manufacturing or raw material availability. To this end, supply chain design takes a critical role to ensure cold redundancies at every step of the supply chain. Simple what-if scenarios can identify the criticality of certain suppliers, subcontractors, types of equipment or regions that are likely to face breakdowns or disruptions.

As we recently witnessed in the aftermath of the cyberattack that hackers carried out against Colonial Pipeline, creating havoc on the East Coast of the U.S. due to fears of a fuel shortage, resiliency is needed not just in the physical supply chain but is critical in the digital supply chain as well. Companies need to ensure their data and IP are well-protected against the growing number of ransomware attacks.

Finally, creating digital supply chain twins to replicate the operations of the supply chain using S&OP and S&OE solutions has helped to provide better visibility for companies and identify their vulnerabilities and how to predict and respond to disruptions. Many companies are focused on the use of S&OP at this stage; however, in order to create a true digital twin, an S&OE solution is needed to provide true predictability and visibility.

Given the changes in the climate, growing regional conflicts, increasing volumes of transportation, digital market places and rising consumer expectations, disruptions in supply chains will only grow stronger and more frequently. As we have recently witnessed, such disruptive forces cause losses of hundreds of millions of dollars every year, so resiliency and digitalization should be critical priority items for every supply chain leader.

Source: https://www.forbes.com/sites/forbestechcouncil/2021/08/04/supply-chain-resiliency---a-critical-lesson-from-covid-19/

Read MoreResiliency also implies having multiple sources of supply from different regions and different suppliers. Given the current geopolitical and socioeconomic dynamics in the world, it is highly unreliable to depend on a single source of manufacturing or raw material availability. To this end, supply chain design takes a critical role to ensure cold redundancies at every step of the supply chain. Simple what-if scenarios can identify the criticality of certain suppliers, subcontractors, types of equipment or regions that are likely to face breakdowns or disruptions.

As we recently witnessed in the aftermath of the cyberattack that hackers carried out against Colonial Pipeline, creating havoc on the East Coast of the U.S. due to fears of a fuel shortage, resiliency is needed not just in the physical supply chain but is critical in the digital supply chain as well. Companies need to ensure their data and IP are well-protected against the growing number of ransomware attacks.

Finally, creating digital supply chain twins to replicate the operations of the supply chain using S&OP and S&OE solutions has helped to provide better visibility for companies and identify their vulnerabilities and how to predict and respond to disruptions. Many companies are focused on the use of S&OP at this stage; however, in order to create a true digital twin, an S&OE solution is needed to provide true predictability and visibility.

Given the changes in the climate, growing regional conflicts, increasing volumes of transportation, digital market places and rising consumer expectations, disruptions in supply chains will only grow stronger and more frequently. As we have recently witnessed, such disruptive forces cause losses of hundreds of millions of dollars every year, so resiliency and digitalization should be critical priority items for every supply chain leader.

Source: https://www.forbes.com/sites/forbestechcouncil/2021/08/04/supply-chain-resiliency---a-critical-lesson-from-covid-19/

Deliver the highest quality product at the lowest possible price with Lean Supply Chain

A lean business aims to deliver the highest quality product at the lowest possible price, which means using few resources as effectively as possible to bring that product to market. Any part of the process that doesn’t actively and directly contribute to that goal is considered waste.

Many points in the supply chain benefit from the lean technique of poka-yoke. This is a mistake-proofing procedure that prevents human error by making it impossible for a task to be done incorrectly. Digitization of the supply chain aids poka-yoka by reducing errors, streamlining the process, and enabling a collaborative framework for resolving issues as they arise. The result is a higher quality product, fewer supply-chain disruptions, quicker resolutions, and improved customer delivery and satisfaction.

The lean principle of 5S also reduces errors by eliminating the wastes that can cause them. The 5S method stands for sort, set in order, shine, standardize, and sustain. Digitizing the supply chain can support a clean, safe, efficient, and uncluttered environment that reduces the odds of human error.

Lean eliminates activities that don’t add value to the customer, and it can help supply chains function more efficiently. Lean targets the greatest sources of waste:

Inventory excess: Building up a greater inventory than customers demand based on speculative forecasting. This results in high inventory costs.

Transportation: Moving materials around more than needed causes increased logistical costs and delivery time.

Poor distribution-facility layout: Causes additional work that adds no value to the product. Lean simplifies distribution to make the supply chain operate more efficiently.

Inefficient pricing: Minimizes profits and revenue while maintaining inventory levels that aren’t needed. It also moves products at rates that hamper the revenue stream.

Poor forecasting and planning across all constituents: Lean and Six Sigma can help coordinate the production plan with the integrated business plan to optimize optimal sales and operations.

Increased revenue: Organizations that use lean and Six Sigma to make their supply chains more efficient provide a consistent service level to their customers.

Reducing the eight potential wastes that can affect a supply chain is a central objective of the lean methodology. The wastes are defects, overproduction, waiting, underutilized talent, transportation, inventory, motion, and extra processing. Perhaps more important is how supply chain analysts determine what is truly wasteful and unnecessary to the process. To do this, lean businesses focus on one variable: whether a process adds value to the customer.

Read MoreMany points in the supply chain benefit from the lean technique of poka-yoke. This is a mistake-proofing procedure that prevents human error by making it impossible for a task to be done incorrectly. Digitization of the supply chain aids poka-yoka by reducing errors, streamlining the process, and enabling a collaborative framework for resolving issues as they arise. The result is a higher quality product, fewer supply-chain disruptions, quicker resolutions, and improved customer delivery and satisfaction.

The lean principle of 5S also reduces errors by eliminating the wastes that can cause them. The 5S method stands for sort, set in order, shine, standardize, and sustain. Digitizing the supply chain can support a clean, safe, efficient, and uncluttered environment that reduces the odds of human error.

Lean eliminates activities that don’t add value to the customer, and it can help supply chains function more efficiently. Lean targets the greatest sources of waste:

Inventory excess: Building up a greater inventory than customers demand based on speculative forecasting. This results in high inventory costs.

Transportation: Moving materials around more than needed causes increased logistical costs and delivery time.

Poor distribution-facility layout: Causes additional work that adds no value to the product. Lean simplifies distribution to make the supply chain operate more efficiently.

Inefficient pricing: Minimizes profits and revenue while maintaining inventory levels that aren’t needed. It also moves products at rates that hamper the revenue stream.

Poor forecasting and planning across all constituents: Lean and Six Sigma can help coordinate the production plan with the integrated business plan to optimize optimal sales and operations.

Increased revenue: Organizations that use lean and Six Sigma to make their supply chains more efficient provide a consistent service level to their customers.

Reducing the eight potential wastes that can affect a supply chain is a central objective of the lean methodology. The wastes are defects, overproduction, waiting, underutilized talent, transportation, inventory, motion, and extra processing. Perhaps more important is how supply chain analysts determine what is truly wasteful and unnecessary to the process. To do this, lean businesses focus on one variable: whether a process adds value to the customer.

Why Outsource your Procurement?

The pandemic placed procurement on a higher level within business operations. Executive boards that previously overlooked or undersold the value of procurement started to sit procurement managers around the table with strategic advisors to mitigate risks, optimise costs, and drive growth.

Procurement teams now race to find skilled, third-party vendors to provide services they can neither afford nor prioritise. For example, expert outside firms can analyse market conditions, supply specialised goods such as semiconductors or uniquely designed parts, and help develop a strong IT infrastructure.

To be clear, if your team can skillfully outsource, a whole new world opens up: you can rapidly adjust to market conditions, scale up when demand spikes, and scale down when dips hit.

Why Outsource your Procurement? First, you can cut costs. Suppliers in Southeast Asia and other low-cost countries can provide large amounts of materials and products at excellent prices without the political backlash that often accompanies offshoring. But outsourcing has several advantages. When you get specialists on board, you can shorten development times, hire additional staff without having to train them, and digitise your procurement systems thanks to IT experts. Additional Benefits are Increases focus on core tasks, Provides staff more time to fulfil their priorities, Supplies next-gen technology expertise, Reduces operational costs, and helps prevent duplicate payments.

These benefits only accrue, however, if your team carefully defines the scope of the operation. When you try to hit the bull’s-eye on a dartboard, you aim directly at the centre. It takes a certain angle, force, and skill. Likewise, procurement teams must figure out what and how much to outsource. Outsourcing still requires spending, and teams will want to get good data before they sign a final contract. In addition, staff members should be on board with the rationale and objectives of the outsourcing project—otherwise, your darts will miss their target.

Source: https://supplychaindigital.com/procurement/procurement-outsourcing-partnering-outside-experts

Read MoreProcurement teams now race to find skilled, third-party vendors to provide services they can neither afford nor prioritise. For example, expert outside firms can analyse market conditions, supply specialised goods such as semiconductors or uniquely designed parts, and help develop a strong IT infrastructure.

To be clear, if your team can skillfully outsource, a whole new world opens up: you can rapidly adjust to market conditions, scale up when demand spikes, and scale down when dips hit.

Why Outsource your Procurement? First, you can cut costs. Suppliers in Southeast Asia and other low-cost countries can provide large amounts of materials and products at excellent prices without the political backlash that often accompanies offshoring. But outsourcing has several advantages. When you get specialists on board, you can shorten development times, hire additional staff without having to train them, and digitise your procurement systems thanks to IT experts. Additional Benefits are Increases focus on core tasks, Provides staff more time to fulfil their priorities, Supplies next-gen technology expertise, Reduces operational costs, and helps prevent duplicate payments.

These benefits only accrue, however, if your team carefully defines the scope of the operation. When you try to hit the bull’s-eye on a dartboard, you aim directly at the centre. It takes a certain angle, force, and skill. Likewise, procurement teams must figure out what and how much to outsource. Outsourcing still requires spending, and teams will want to get good data before they sign a final contract. In addition, staff members should be on board with the rationale and objectives of the outsourcing project—otherwise, your darts will miss their target.

Source: https://supplychaindigital.com/procurement/procurement-outsourcing-partnering-outside-experts

A balance between flexibility, resilience and cost efficient supply chain

In a restricted supply chain operation, the organization should identify, carefully analyze and ascertain the “real” need of the raw material /products etc. Short and medium term planning is advisable as long term strategic planning should only be done if the Supply Chain Managers properly foresee the future of markets. What to order, when to order and How much to order should be determined by MRP using the basic principles of procurement such as future demand, stock in hand with safety stock, on way stocks, lead times prevailing during pandemic, production delays if any, port congestion and possible delays, transport availability etc.

The top management of organizations should take control of the Supply Chain during the pandemic and needs to manage and control the supply chain at every stage or phase ensuring the smooth flow towards the end customer. Supply Chain Management is key to the success and increased performance of a supply chain. Companies looking to change their supply chains should consider how to integrate elements and practices around environmental protection, product sustainability and ethical business practices.

Radically changing an existing supply chain is not as easy as it may sound as creating a robust and secure supply chain will need to balance the demands for cost efficiency. At the same time, new logistics considerations may also have an impact on supply chains and the changes thereto. In the short and medium term, it is expected that companies will begin to search for more diversified supplier base while looking to develop a flexible and a resilient but cost efficient supply chain.

Source: http://island.lk/debottlenecking-the-strained-supply-chain-during-covid-19-pandemic-and-beyond/

Read MoreThe top management of organizations should take control of the Supply Chain during the pandemic and needs to manage and control the supply chain at every stage or phase ensuring the smooth flow towards the end customer. Supply Chain Management is key to the success and increased performance of a supply chain. Companies looking to change their supply chains should consider how to integrate elements and practices around environmental protection, product sustainability and ethical business practices.

Radically changing an existing supply chain is not as easy as it may sound as creating a robust and secure supply chain will need to balance the demands for cost efficiency. At the same time, new logistics considerations may also have an impact on supply chains and the changes thereto. In the short and medium term, it is expected that companies will begin to search for more diversified supplier base while looking to develop a flexible and a resilient but cost efficient supply chain.

Source: http://island.lk/debottlenecking-the-strained-supply-chain-during-covid-19-pandemic-and-beyond/

Keunggulan kebijakan logistik Pemerintah Indonesia dibandingkan negara maju dalam menghadapi pandemi

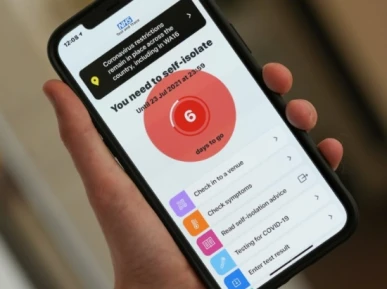

ORSI NEWS | - "Pingdemic" merupakan sebuah istilah baru yang saat ini menjadi cukup menjadi viral di Inggris yang berarti seseorang telah terlacak oleh suatu "mobile application" yang dijalankan National Health Service (Organisasi Pemerintah Inggris yang melakukan pelayanan medis dan perawatan kesehatan) pernah melakukan kontak secara langsung dengan seseorang yang telah menerima hasil test positif Covid-19. Seseorang yang menerima notifikasi tersebut wajib melakukan isolasi mandiri selama 10 hari tanpa terkecuali, dan dapat diperpanjang jika selama isolasi yang bersangkutan terindikasi memiliki gejala covid-19.

Lebih dari setengah juta warga inggris telah menerima "ping" dari aplikasi tersebut hingga awal juli 2021 lalu dan jumlahnya terus bertambah hingga hari ini, hal tersebut mengakibatkan terjadinya krisis kekurangan tenaga kerja di sektor logistik, distribusi hingga industri pangan dan kebutuhan sehari-hari, yang berimbas dengan terjadinya kelangkaan barang kebutuhan pokok dan kebutuhan sehari-hari di berbagai supermarket di Inggris. Banyak rak-rak di supermarket kosong karena tidak mendapat suplai, berbagai fasilitas logistik hingga pelabuhan beroperasi dengan sangat terbatas karena kekurangan tenaga kerja di lapangan.

Namun dalam upaya untuk mencegah kelangkaan produk konsumsi, rak supermarket yang lebih kosong dan mencegah kerusakan ekonomi yang lebih luas, Pemerintah Inggris pada hari Kamis lalu akhirnya harus tunduk pada tekanan terus-menerus dari industri makanan, sehingga mengumumkan bahwa sekitar 10.000 pekerja di sektor ini akan dibebaskan dari aturan "Pingdemic" ini jika para pekerja bersedia melakukan tes covid-19 dan menunjukan hasil negatif setiap harinya. Namun pelaksanaan komunikasi kebijakan baru tersebut berjalan dengan tidak baik dan memperburuk krisis, para pelaku usaha di UK merasa belum tahu siapa yang sebenarnya ada dalam daftar kelompok yang dikecualikan. Dari 500 bisnis yang seharusnya disertakan, hanya 3% yang merasa telah terinformasi dengan baik.

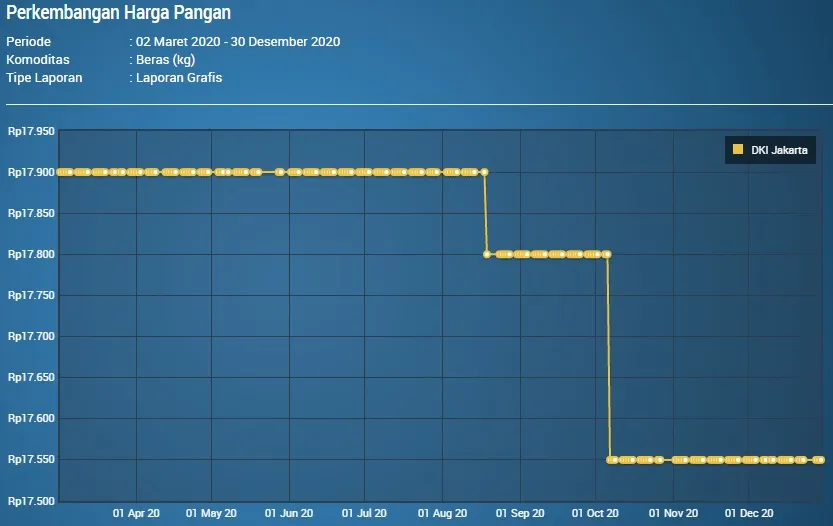

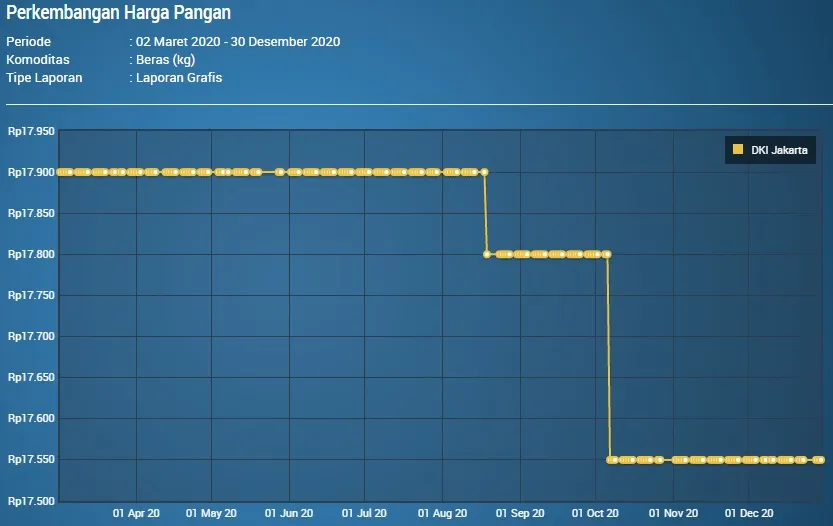

Sebaliknya berbeda dengan penanganan kebijakan sektor logistik di Indonesia sejak awal terjadinya Covid-19 pada awal tahun 2020, sejak kebijakan pembatasan pergerakan masyarakat yang pertamakali dikenal sebagai Pembatasan Sosial Berskala Besar (PSBB), Pemerintah dengan lugas telah memberikan pengecualian pembatasan kerja kepada kantor atau instansi tertentu yang memberikan pelayanan terkait dengan pertahanan dan keamanan, ketertiban umum, kebutuhan pangan, bahan bakar minyak dan gas, pelayanan kesehatan, perekonomian, keuangan, komunikasi, industri, ekspor dan impor, distribusi, logistik, dan kebutuhan dasar lainnya. Kebijakan tersebut pun juga telah berhasil dikomunikasikan dengan baik dan efektif, sehingga di Indonesia walaupun sempat terjadi "panic buying" pada awal pandemi, namun belum pernah terjadi kelangkaan produk pangan ataupun kebutuhan sehari-hari yang berlangsung dengan periode yang lama, bahkan menurut data PIHPS Nasional tercatat pada periode Maret 2020 hingga Desember 2020 secara umum terjadi penurunan harga komoditas beras dari semula Rp 17.900/kg menjadi Rp. 17.550/kg.

Semoga kedepan, Pemerintah Indonesia dan para ahli terkait terus mampu dapat membuat kebijakan logistik dan rantai suplai nasional terbaik sehingga masyarakat dapat terus terhindar dari kelangkaan produk pangan dan kebutuhan sehari-hari, dan juga mampu segera mengatasi permasalahan kelangkaan oksigen akibat meningkatnya jumlah pasien yang dirawat akibat covid-19 dan juga "panic buying" produk oksigen yang sempat terjadi beberapa waktu yang lalu.

Salam Sehat & Produktif,

R. Beniadi Setiawan, ST,MM,MMBA(SC),PMP(SC),CPLSC,CPGN,CPP,CPL,CPC.

Principal Consultant & International Trainer

Read MoreLebih dari setengah juta warga inggris telah menerima "ping" dari aplikasi tersebut hingga awal juli 2021 lalu dan jumlahnya terus bertambah hingga hari ini, hal tersebut mengakibatkan terjadinya krisis kekurangan tenaga kerja di sektor logistik, distribusi hingga industri pangan dan kebutuhan sehari-hari, yang berimbas dengan terjadinya kelangkaan barang kebutuhan pokok dan kebutuhan sehari-hari di berbagai supermarket di Inggris. Banyak rak-rak di supermarket kosong karena tidak mendapat suplai, berbagai fasilitas logistik hingga pelabuhan beroperasi dengan sangat terbatas karena kekurangan tenaga kerja di lapangan.

Namun dalam upaya untuk mencegah kelangkaan produk konsumsi, rak supermarket yang lebih kosong dan mencegah kerusakan ekonomi yang lebih luas, Pemerintah Inggris pada hari Kamis lalu akhirnya harus tunduk pada tekanan terus-menerus dari industri makanan, sehingga mengumumkan bahwa sekitar 10.000 pekerja di sektor ini akan dibebaskan dari aturan "Pingdemic" ini jika para pekerja bersedia melakukan tes covid-19 dan menunjukan hasil negatif setiap harinya. Namun pelaksanaan komunikasi kebijakan baru tersebut berjalan dengan tidak baik dan memperburuk krisis, para pelaku usaha di UK merasa belum tahu siapa yang sebenarnya ada dalam daftar kelompok yang dikecualikan. Dari 500 bisnis yang seharusnya disertakan, hanya 3% yang merasa telah terinformasi dengan baik.

Sebaliknya berbeda dengan penanganan kebijakan sektor logistik di Indonesia sejak awal terjadinya Covid-19 pada awal tahun 2020, sejak kebijakan pembatasan pergerakan masyarakat yang pertamakali dikenal sebagai Pembatasan Sosial Berskala Besar (PSBB), Pemerintah dengan lugas telah memberikan pengecualian pembatasan kerja kepada kantor atau instansi tertentu yang memberikan pelayanan terkait dengan pertahanan dan keamanan, ketertiban umum, kebutuhan pangan, bahan bakar minyak dan gas, pelayanan kesehatan, perekonomian, keuangan, komunikasi, industri, ekspor dan impor, distribusi, logistik, dan kebutuhan dasar lainnya. Kebijakan tersebut pun juga telah berhasil dikomunikasikan dengan baik dan efektif, sehingga di Indonesia walaupun sempat terjadi "panic buying" pada awal pandemi, namun belum pernah terjadi kelangkaan produk pangan ataupun kebutuhan sehari-hari yang berlangsung dengan periode yang lama, bahkan menurut data PIHPS Nasional tercatat pada periode Maret 2020 hingga Desember 2020 secara umum terjadi penurunan harga komoditas beras dari semula Rp 17.900/kg menjadi Rp. 17.550/kg.

Semoga kedepan, Pemerintah Indonesia dan para ahli terkait terus mampu dapat membuat kebijakan logistik dan rantai suplai nasional terbaik sehingga masyarakat dapat terus terhindar dari kelangkaan produk pangan dan kebutuhan sehari-hari, dan juga mampu segera mengatasi permasalahan kelangkaan oksigen akibat meningkatnya jumlah pasien yang dirawat akibat covid-19 dan juga "panic buying" produk oksigen yang sempat terjadi beberapa waktu yang lalu.

Salam Sehat & Produktif,

R. Beniadi Setiawan, ST,MM,MMBA(SC),PMP(SC),CPLSC,CPGN,CPP,CPL,CPC.

Principal Consultant & International Trainer

Menghemat penggunaan jutaan lembar kertas tiap tahun dengan memaksimalkan proses digitalisasi rantai suplai secara nasional, yang diprediksi juga akan menurunkan deforestasi hutan Indonesia

ORSI NEWS | - Kementrian Lingkungan Hidup dan Kehutanan Republik Indonesia (KLHK) mengatakan bahwa penurunan luas hutan (deforestasi) di Indonesia sudah dalam level yang memperihatinkan, bahkan hal tersebut turut memberi andil dalam terjadinya bencana banjir di Kalimantan Selatan pada awal tahun ini. Perusahaan bubur kertas (pulp) disinyalir juga berperan dalam meningkatnya deforestasi hutan-hutan di Indonesia.

Digitalisasi rantai suplai dapat menghemat jutaan lembar kertas pertahun jika proses digitaliasi dapat dilakukan secara maksimal dalam tiap value chain berbagai sektor industri di Indonesia, khususnya pada penggunaan dokumen kertas (hardcopy) di proses pengadaan, pengiriman / transportasi dan pergudangan. Selain itu digitalisasi rantai suplai akan meningkatkan data transparency dan visibility yang akan menjadi modal yang sangat penting bagi management untuk proses pengambilan keputusan yang lebih efektif.

Adopsi digitalisasi rantai suplai sudah sangat perlu didukung oleh Pemerintah agar dapat berdampak lebih maksimal, dikarenakan saat ini kurang dari 20% industri telah memanfaatkan teknolongi digital dalam kegiatan operasinya.

Karena rendahnya kesadaran proses digitalisasi rantai suplai di Indonesia tersebut, saat ini masih terdapat cukup banyak dokumen berbahan kertas yang terlibat dalam kegiatan rantai suplai diberbagai sektor industri dan perdagangan , sebagai contoh dalam kegiatan logistik pengiriman barang dengan tujuan internasional, satu proses pengiriman barang ke tujuan internasional akan membutuhkan secara total lebih dari 25 halaman dokumentasi untuk berbagai kebutuhan. Dengan asumsi lebih dari 15 juta pengiriman setiap tahun, maka jumlah lembaran kertas yang digunakan mencapai jumlah yang mengejutkan yaitu 375 juta lembar kertas pertahunnya hanya untuk mendukung kegiatan eksport.

Salam Sehat & Produktif,

R. Beniadi Setiawan, ST,MM,MMBA(SC),PMP(SC),CPLSC,CPGN,CPP,CPL,CPC.

Principal Consultant & International Trainer

Read MoreDigitalisasi rantai suplai dapat menghemat jutaan lembar kertas pertahun jika proses digitaliasi dapat dilakukan secara maksimal dalam tiap value chain berbagai sektor industri di Indonesia, khususnya pada penggunaan dokumen kertas (hardcopy) di proses pengadaan, pengiriman / transportasi dan pergudangan. Selain itu digitalisasi rantai suplai akan meningkatkan data transparency dan visibility yang akan menjadi modal yang sangat penting bagi management untuk proses pengambilan keputusan yang lebih efektif.

Adopsi digitalisasi rantai suplai sudah sangat perlu didukung oleh Pemerintah agar dapat berdampak lebih maksimal, dikarenakan saat ini kurang dari 20% industri telah memanfaatkan teknolongi digital dalam kegiatan operasinya.

Karena rendahnya kesadaran proses digitalisasi rantai suplai di Indonesia tersebut, saat ini masih terdapat cukup banyak dokumen berbahan kertas yang terlibat dalam kegiatan rantai suplai diberbagai sektor industri dan perdagangan , sebagai contoh dalam kegiatan logistik pengiriman barang dengan tujuan internasional, satu proses pengiriman barang ke tujuan internasional akan membutuhkan secara total lebih dari 25 halaman dokumentasi untuk berbagai kebutuhan. Dengan asumsi lebih dari 15 juta pengiriman setiap tahun, maka jumlah lembaran kertas yang digunakan mencapai jumlah yang mengejutkan yaitu 375 juta lembar kertas pertahunnya hanya untuk mendukung kegiatan eksport.

Salam Sehat & Produktif,

R. Beniadi Setiawan, ST,MM,MMBA(SC),PMP(SC),CPLSC,CPGN,CPP,CPL,CPC.

Principal Consultant & International Trainer

Ragu untuk pindah atau memulai karir pada bidang rantai suplai?

ORSI NEWS | - Di saat kegiatan dunia usaha sedang melambat akibat dampak penerapan Pemberlakuan Pembatasan Kegiatan Masyarakat (PPKM) khususnya pada sektor usaha Perdagangan, Perhotelan, Restoran, Keuangan, serta jasa Transportasi, bahkan tidak sedikit hingga harus menghentikan kegiatan usahanya, disaat yang sama transaksi penjualan secara online / daring melalui e-Commerce meningkat cukup signifikan. Salah satu pelaku usaha e-Commerce, Tokopedia menginformasikan bahwa selama periode PPKM Darurat telah terjadi lonjakan penjualan hingga dua kali lipat dari sebelum PPKM Darurat diberlakukan. Kementrian Perdagangan Republik Indonesia telah memproyeksikan nilai transaksi e-Commerce yang saat ini menguasai 34% pasar digital di Indonesia pada tahun 2030 akan meningkat cukup tajam, hingga dapat mencapai Rp. 1.908 trilliun. Kenaikan tersebut diproyeksikan akan diikuti dengan meningkatnya industri penunjang.

Begitu pula pada sektor kegiatan usaha jasa logistik yang telah menikmati peningkatan jumlah pengiriman barang sekitar 30% sejak pandemi Covid-19 berlangsung, hal tersebut mendorong pesatnya kebutuhan layanan logistik pergudangan, jasa kurir dan fulfilment centers.

Ditengah perlambatan ekonomi yang sedang terjadi seperti saat ini, sudah cukup banyak pelaku usaha merumahkan karyawannya bahkan mengurangi jumlah karyawan melalui mekanisme Pemutusan Hubungan Kerja (PHK). Namun kondisi tersebut sangat berbeda dengan pelaku usaha pada sektor logistik yang justru sedang berkembang pesat dan membutuhkan berbagai sumberdaya baru seperti tambahan fasilitas lapangan, gudang, tenaga kerja dan lain sebagainya mengakibatkan terciptanya kesempatan kerja baru pada sektor usaha logistik ataupun rantai suplai.

Dengan pertimbangan berbagai hal tersebut diatas, memilih untuk memulai karir atau ingin mempertahankan karirnya pada fungsi manajemen rantai suplai (Supply Chain Management) adalah pertimbangan yang sangat ideal untuk dipilih.

Selain itu dengan meningkatnya sektor usaha logistik dan rantai suplai, penghasilan para professional yang bekerja pada fungsi terkait operasi logistik dan rantai suplai telah mengalami peningkatan penghasilan secara umum menjadi sekitar 20% lebih tinggi daripada median penghasilan untuk pekerja di industri lain dengan masa kerja, kualifikasi dan pendidikan yang sama, belum termasuk potensi tambahan penghasilan melalui mekanisme bonus dan insentif.

Lowongan pekerjaan pada bidang rantai suplai, khususnya logistik dan pergudangan, saat ini cukup banyak dan terbuka, serta diprediksi akan terus tumbuh seiring dengan ekspansi para perusahaan penyedia jasa logistik yang terus membuka fasilitas gudang / distribution center yang baru diseluruh wilayah nusantara.

Yang juga membuat berkarir dibidang rantai suplai menjadi sangat menarik adalah para professional rantai suplai cukup menikmati luasnya area fungsi pekerjaan di bidang rantai suplai baik secara vertikal maupun horisontal, mulai dari fungsi pengadaan, inventory control, pergudangan, transportasi kargo, distribusi dan lain sebagainya. Mulai dari level junior analyst hingga dapat menjadi seorang Chief Supply Chain Officer atau yang juga dikenal sebagai Direktur Rantai Suplai.

Pilihan untuk memulai karir pada bidang profesi rantai suplai, saat ini merupakan salah satu pilihan yang terbaik yang dapat diambil oleh para "Talent Ready" atau para Pencari Kerja di Indonesia, dengan penghasilan yang relatif lebih baik dibandingkan bidang usaha lainnya dan ditopang dengan pertumbuhan kegiatan usaha rantai suplai, khususnya pada sektor usaha logistik, yang sangat pesat dalam waktu 5 tahun terakhir.

R. Beniadi Setiawan, ST,MM,MMBA(SC),PMP(SC),CPLSC,CPGN,CPP,CPL,CPC.

Principal Consultant & International Trainer

Read MoreBegitu pula pada sektor kegiatan usaha jasa logistik yang telah menikmati peningkatan jumlah pengiriman barang sekitar 30% sejak pandemi Covid-19 berlangsung, hal tersebut mendorong pesatnya kebutuhan layanan logistik pergudangan, jasa kurir dan fulfilment centers.

Ditengah perlambatan ekonomi yang sedang terjadi seperti saat ini, sudah cukup banyak pelaku usaha merumahkan karyawannya bahkan mengurangi jumlah karyawan melalui mekanisme Pemutusan Hubungan Kerja (PHK). Namun kondisi tersebut sangat berbeda dengan pelaku usaha pada sektor logistik yang justru sedang berkembang pesat dan membutuhkan berbagai sumberdaya baru seperti tambahan fasilitas lapangan, gudang, tenaga kerja dan lain sebagainya mengakibatkan terciptanya kesempatan kerja baru pada sektor usaha logistik ataupun rantai suplai.

Dengan pertimbangan berbagai hal tersebut diatas, memilih untuk memulai karir atau ingin mempertahankan karirnya pada fungsi manajemen rantai suplai (Supply Chain Management) adalah pertimbangan yang sangat ideal untuk dipilih.

Selain itu dengan meningkatnya sektor usaha logistik dan rantai suplai, penghasilan para professional yang bekerja pada fungsi terkait operasi logistik dan rantai suplai telah mengalami peningkatan penghasilan secara umum menjadi sekitar 20% lebih tinggi daripada median penghasilan untuk pekerja di industri lain dengan masa kerja, kualifikasi dan pendidikan yang sama, belum termasuk potensi tambahan penghasilan melalui mekanisme bonus dan insentif.

Lowongan pekerjaan pada bidang rantai suplai, khususnya logistik dan pergudangan, saat ini cukup banyak dan terbuka, serta diprediksi akan terus tumbuh seiring dengan ekspansi para perusahaan penyedia jasa logistik yang terus membuka fasilitas gudang / distribution center yang baru diseluruh wilayah nusantara.

Yang juga membuat berkarir dibidang rantai suplai menjadi sangat menarik adalah para professional rantai suplai cukup menikmati luasnya area fungsi pekerjaan di bidang rantai suplai baik secara vertikal maupun horisontal, mulai dari fungsi pengadaan, inventory control, pergudangan, transportasi kargo, distribusi dan lain sebagainya. Mulai dari level junior analyst hingga dapat menjadi seorang Chief Supply Chain Officer atau yang juga dikenal sebagai Direktur Rantai Suplai.

Pilihan untuk memulai karir pada bidang profesi rantai suplai, saat ini merupakan salah satu pilihan yang terbaik yang dapat diambil oleh para "Talent Ready" atau para Pencari Kerja di Indonesia, dengan penghasilan yang relatif lebih baik dibandingkan bidang usaha lainnya dan ditopang dengan pertumbuhan kegiatan usaha rantai suplai, khususnya pada sektor usaha logistik, yang sangat pesat dalam waktu 5 tahun terakhir.

R. Beniadi Setiawan, ST,MM,MMBA(SC),PMP(SC),CPLSC,CPGN,CPP,CPL,CPC.

Principal Consultant & International Trainer